Quick Details

Place of Origin: Jiangsu, China (Mainland)

Brand Name: COMAC

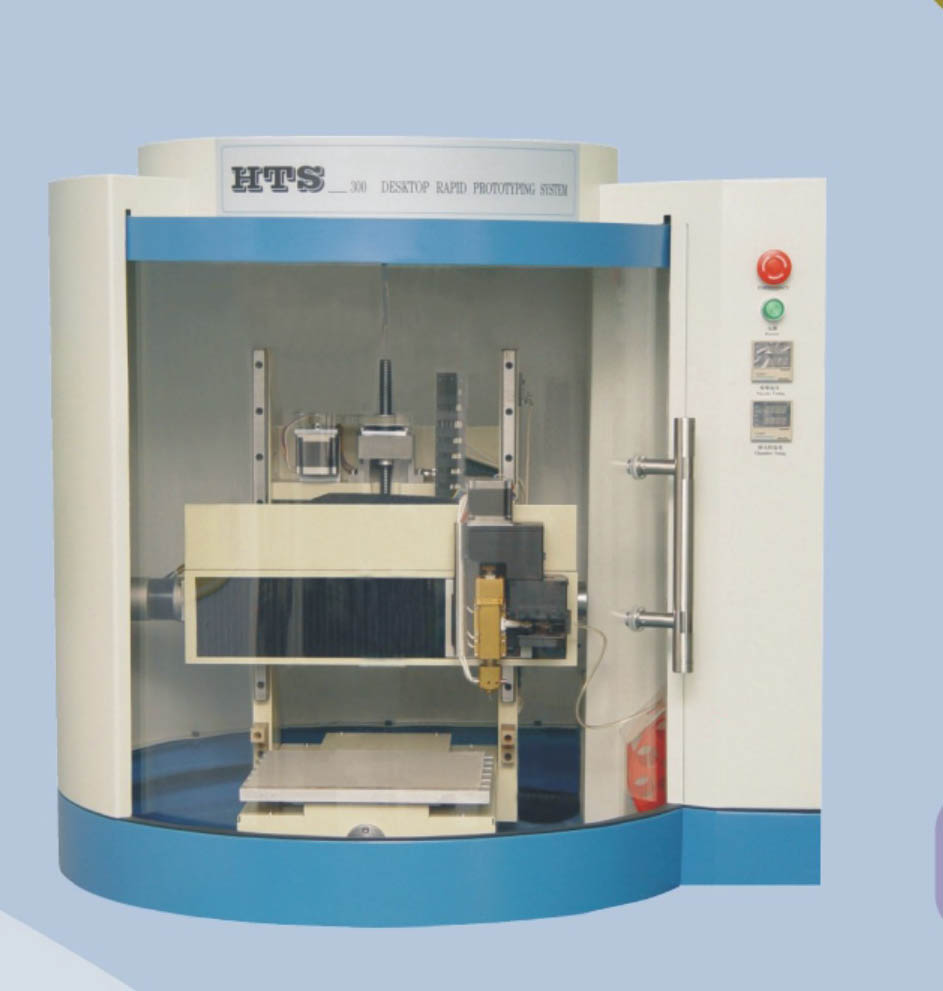

Model Number: HT-300

Home

> Products

> CNC training system > Details

Home

> Products

> CNC training system > Details

Prev:Rapid Prototyping Machine

Next:Is the last one

Place of Origin: Jiangsu, China (Mainland)

Brand Name: COMAC

Model Number: HT-300

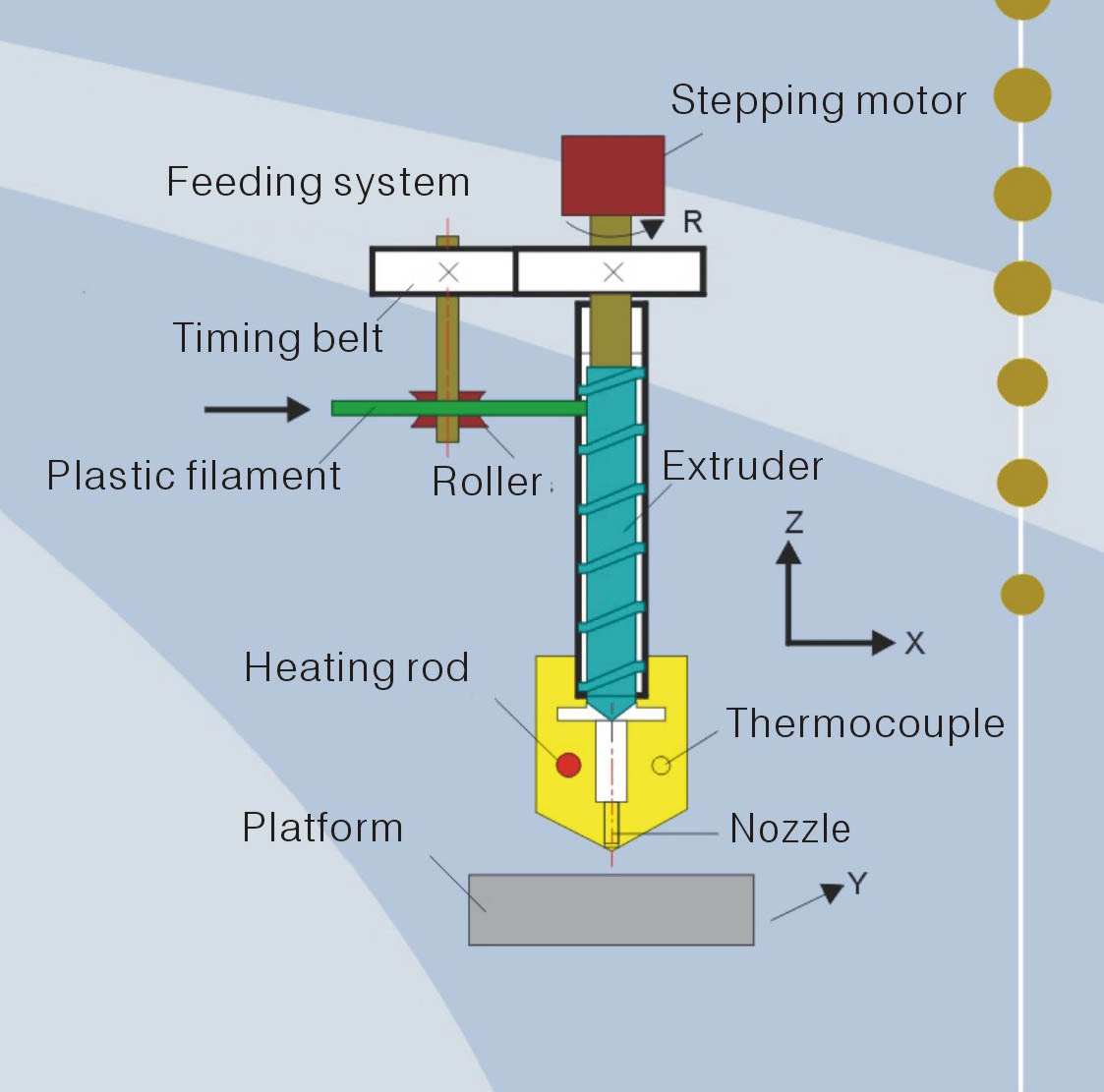

The Principle of HT Rapid Prototyping System HT is a high efficiency desktop rapid prototyping system, it consists of gantry frame, platform movable along Y direction, worm extruder movable along direction X and Z, filament material feeding system, and control system. The extruder and the feeding system are driven by the same step motor. Once the external PC sends control signal the worm is driven by the step motor , meanwhile, the plastic filament is fed into the extruding cylinder through a timing belt or gearsand roller mechanism. Then the plastic filament is melted by a heating rod embedded in the brass nozzle and deposited on the platform. The external PC calculates the cross section data alone Z direction of 3D model of object and the deposition path for each cross section. The deposition path data is then transferred to control system, each layer is built by the resultant motion of platform and extruder. After one layer is built, the extruder is raised a layer thickness (usually about 0.1 mm), the next layer is then build, the steps as above are repeated until the object is formed. The Characteristics 1. High pressure worm extruder, high form efficiency. It is possible to make high strength plastic object. 2. Ingenuity gantry frame, lower driven inertia, high speed. 3. Attachment filament making system. End user can customize the material according to his requirement. 4. Contour filling pattern, higher strength of formed object. 5. Small system volume, lower noise, lower vibration. It is suitable for office environment application. 6. Economic system makes it possible to be widely used for various industry. The Specifications Model HT-300 HT-400 Build volume (mm) 280×250×300 360×320×400 Part accuracy (mm0 ± 0.2 ± 0.2 Maximum speed (mm/sec) 100 Drive system X and Y axesservo motor , precision lead screw, precision linear guide Z axisstep motor, precision ball screw, precision linear guide Temperature control system Real-time temperature control system Slicing software HT slicing software External computer PC File input format STL format Material Plastic filament, diameter 4 mm Power 220V ,50Hz , 6 A Environment requirement Air condition System size (mm) 950×820×900 950×820×1050 System weight (kg) 120 150Packaging & Delivery

Packaging Details: in export wooden case Delivery Detail: 30 days after order Specifications

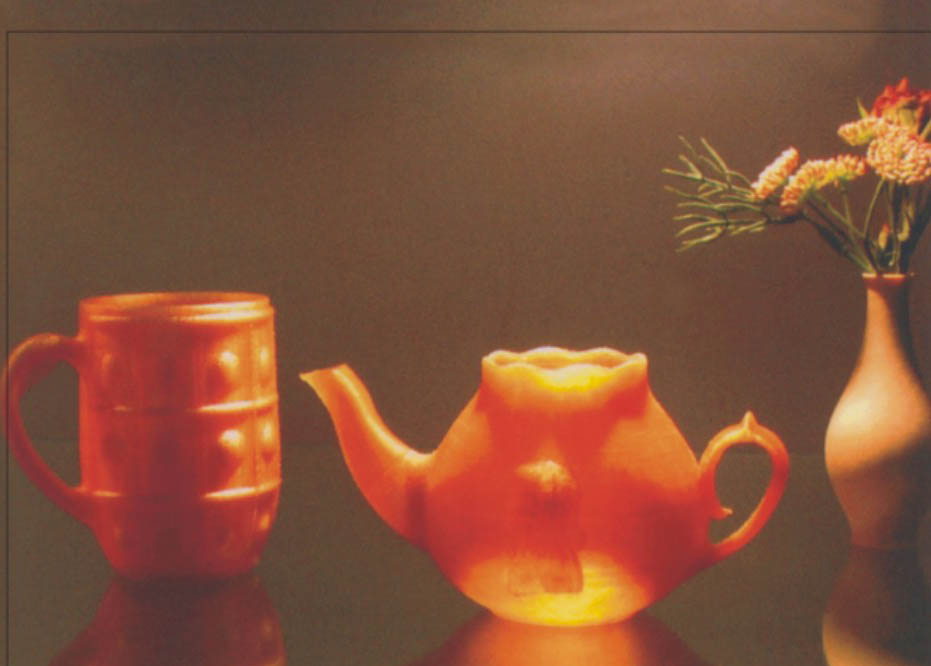

Rapid prototyping machine is very helpful to prototype the design of the students, even for industial, it can help the engineer.